Meta Description: Is your mini excavator not working well, or stop working? Do you face challenges in completing your tasking with a mini excavator? Read to learn how to troubleshoot these issues!

Maybe you are worried because of all these situations. It may also be possible that several things have affected your HIXEN Mini Excavator functionality. In that case, you should not sit back and relax. Try to find out the issue or, if possible, try to notice early warnings. Worried about breaking trustable and reputed connections with customers?

This guide will explore the ways to fix your mini excavator’s final drive. So you can get some preventive approaches to boost your business.

Troubleshooting Your Final Drive Motor

As the final drive motor undergoes many common issues. But the following are some major issues. So let’s talk about all these issues in detail:

1. Noise:

Your mini machine may undergo some noisy issues. You may consider it common noise, but most of the time, it is a new noise. It means you should pay attention to this new noise.

Lubrication

Though there are many causes of new or bad noise in your final drive. The two most common are lacking gear oil and damaged bearings. Both these causes become the major and worse problem that you must address. So make sure to check the level of gear oil. If it is low, then fill it to the correct level.

Bearings

The lifespan of the machine bearing may be limited. It is just because the level of gear oil is not sufficient. As a result, bearings start damaging and cause bad noise. In that case, make sure to check the gear oil level. If it is ok, then you must replace the bearing to avoid such noise.

Gears

Another cause of bad noise in the final drive is the damage to gears and blades. However, both gears and blades damage with time. So you should make sure to replace them as early as possible, as the lifespan of gears is more than bearings. But if you notice pointed ends of gears, it means they need replacement.

Weak Charge Pump

The final drive motor produces different types of noises. When you start the motor, it produces grinding noise. Then this noise turns to low pitched roar at low speed. At the same time, it turns into a high-pitched moan at high speed. This continuous changing of noises is because of the weak charge pump.

2. Vibration:

Vibration is another major issue in the final drive motor. Though this issue could be a better thing and causes a loose connection. Also, this issue causes surface damage. Let’s talk about some causes of vibration in your final drive motor:

Loose Projection

Suppose you feel a vibration in your mini excavator during operation. Then it is because of loose projection. Fortunately, this issue is minor. So you can fix, tighten or replace projection bolts.

Internal Damage

Suppose the cause of vibration is not a loose projection. At the same time, your motor is shaking much more. Then it points out the most severe issue in your final drive motor. Commonly this severe issue refers to internal damage. So try to maintain such damage early. Otherwise, it will become worsen and won’t be maintained later.

3. Overheating:

The heating of the machine during operation is a common thing. But overheating or steam coming out of the engine is not a good thing. The following are some main causes of overheating:

Gear Oil Levels

A low level of gear oil means more resistance. More resistance means more production of heat. As a result, this extra heat doesn’t go away from the key components. It means less gear oil is the major cause of overheating. So make sure to maintain the gear oil level in the final drive motor. Also, if necessary, change the oil as early as possible.

Hydraulic Fluid

You have replaced the gear oil, and its level always remains enough. But still, your final drive motor remains overheated. Then it may be because of overheating of hydraulic fluid. So make sure to check the hydraulic fluid level and temperature. The temperature of the fluid must be 180°F, not more than that. While in case the temperature exceeds this range. Then it would be best if you cooled the hydraulic fluid.

Brakes

After checking the hydraulic fluid and gear oil level, the next thing you must check is the brakes. May be brakes are not releasing properly. In that case, these cause resistance and overheating.

Bearings

The last cause of overheating of the final drive motor is the damaged bearings. However, bearings minimize resistance and support the machine. But if these start damaging, then more resistance is produced.

4. Leaks:

Leaks are another major issue in your final drive motor. Leak cause enters of dust and oil and the exit of fluid. So if you notice any such leaking issues, then you must try to find the part which is leaking.

Gear Oil

Gear oil is the thick fluid that may leak from the final drive motor. If you notice leaking of fluid from the projection or area where the projected is fixed. Then it is because of the mechanical seal.

Another cause of the leaking of gear oil is when you fill the drive with more oil. Then it starts leaking out, and you need to find the area of leaking.

Hydraulic Fluid

Hydraulic fluid is a thin fluid compared to gear oil. So when it starts leaking, you can see more of it. The major cause of hydraulic fluid leaking is the hose leak or internal seal. So you have to fix all these issues to avoid hydraulic fluid leaking.

Is the power loss on just one side?

Loss of power on one side of the final drive led to the drifting of the machine on that side. It means if the power loss is on the left side, your machine will only drift to the left side. So make sure to check the track tension and keep it loose, not too tight. Also, make sure to check the tracks to see if there is any debris.

If your HIXEN Mini Excavator motor is drifting on one side, it does not mean the problem is only here. You also need to check the speed of the drive motor and also the brakes. It is also good to check the charge pump of the final drive motor.

Suppose you don’t notice such issues in your final drive motor. Then it is time to repair your drive to keep it in good condition. Most of the time, some parts of the motor are damaged and contaminated.

Is the power loss on both sides?

Yes, the motor can lose power on both sides. It is because when you have to move uphill with more load on the motor. This issue arises if the tracks of both sides are too tight. As a result, these cause resistance and inefficiency, which leads to power loss.

Another cause of power loss is the weak charge pump and faulty brakes. In mini excavators, another cause of power loss is swivel joints. These prevent the reach of hydraulic fluid to the final drive motor.

Create A Plan to Preserve Your Equipment

Having a maintenance plan and schedule is necessary to keep the machine in the right condition. But this step is not enough; you also need to hire an equipment master. The master must have the skills to maintain one specific piece of equipment and all its parts.

When the master notices bad noise and vibration in the machine, so he tries to find and fix the issue as soon as possible. This way, he can save you from spending lots of dollars later. Simply put, having an expert is necessary to address all issues early. This case is more necessary if the machine rotates among different workers.

Create A Daily Routine

To maintain and keep your machine in good condition, you have to create a daily routine as follows:

Morning Start-Up:

Before starting the machine, try to walk around it to check everything. Make sure to check the drive seal, leakage, charge pump, hydraulic fluid, and gear oil. Also, check the noise of the machine if it is bad.

End-of-the-Day Shutdown:

The next inspection is at the end of the day when you shut down the machine. At this time, make sure to check for leaks, overheating, and other things.

Conclusion:

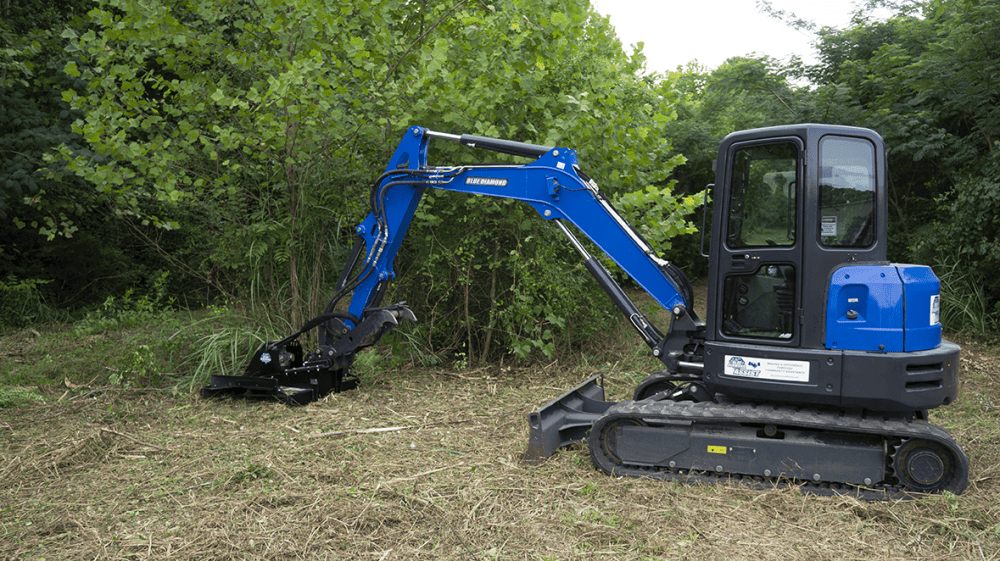

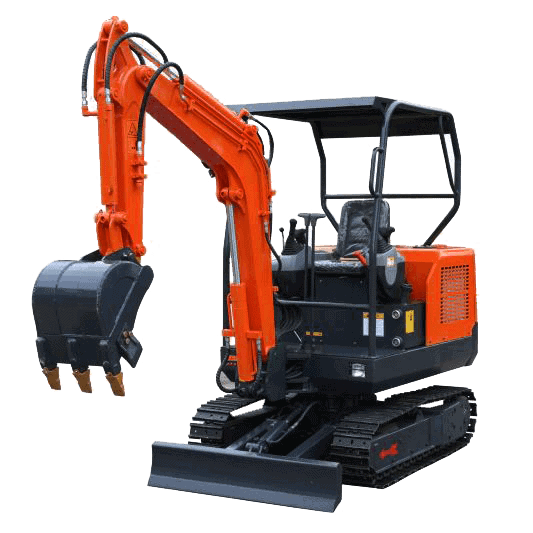

A mini excavator is the most famous and useful machine. So it undergoes many issues as many other machines undergo. The most common problem you may often need help with is the failure of the final drive. To overcome these issues, we have discussed some machine-fixing methods.

If you are not experienced in fixing your machine, then don’t try to do it because you will only damage your machine. So ask the hydraulic repair expert to help you fix your machine. The expert will also assure you that this issue will not happen again!