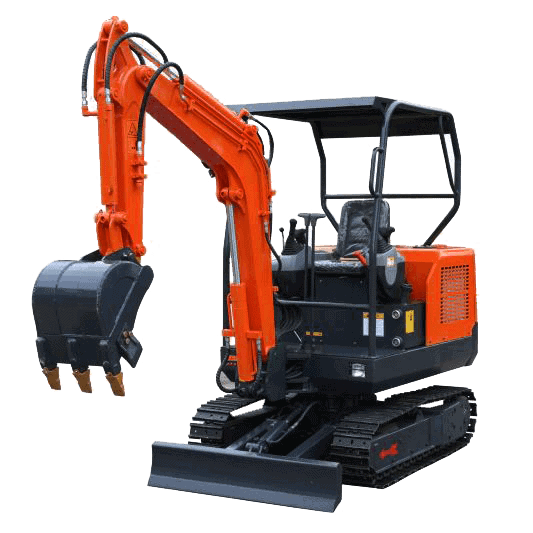

Mini excavators are also called compact excavators. As the name suggests, this machine is small in size and less in weight. The less weight of this machine is just because of its compact size. Moreover, this machine is similar to large excavators. But the tasks it performs are just beyond the standard machines.

Though the digging depth is limited, this machine. So mini excavators can easily work and move in tight areas. Moreover, the common applications of mini machines are:

- Landscaping

- Repairing

- Installation

- Renovation

- Construction and more

Commonly the weight of the machine is determined by the total operating weight. This total weight also includes the weight of attachments. So operators must know the operating weight. This way, as an operator, you can operate the machine safely. Moreover, you must ensure that the machine is the right fit for the working site.

This blog will describe the operating weight of a mini excavator. Moreover, we will also explore some other specs and tips. So you will be able to make the right decision to choose the right machine.

THE MOST COMMONLY USED TYPES OF EXCAVATORS

Have you decided to purchase the excavator? Do you know what the requirements of your project are? If yes, then you can easily find the right excavator according to your requirements.

Now the question is, which category will suit you best? For this, you have to read this section. Here we have grouped different types of excavators based on weight. So let’s take a look at each group in detail:

HIXEN Mini excavators:

Another name for mini excavators is compact excavators. As we have discussed earlier, this excavator is small in size. So HIXEN Mini Excavators also have less weight of almost 5,000 and 14,000 lbs. Moreover, mini excavators are mobile and quick. The better feature of mini excavators is that they can work in tight areas.

Moreover, this machine is an ideal option for many intense jobs. Whether you want to dig, repair, renovate or construct in sensitive areas. The compact machine must be your first choice. The reason is that this machine can ensure the safety of utility lines.

The only drawback of mini excavators is that they have less power. But still, these are used in many projects. Moreover, it can also keep the balance and improve performance.

Medium-rated excavators:

Another type of excavator is a medium excavator. These are large and small. Commonly the weight of these excavators lies between 14,000 and 90,000 lbs. As we know, mini-machines are used in small areas.

While mid-size excavators are ideal in areas where a high-capacity machine is required, so this machine can easily handle tasks of sidewalks and roads. Moreover, this machine is an ideal choice for many projects away from buildings.

Large excavators:

The last type is large excavators. The common weight of this machine is almost 90,000 lbs., which is why the machine is better in many industries. The major use of large excavators is in mining rather than construction. Moreover, the power of large excavators is high, with more working capacity.

But the only drawback of this machine is that it is not suitable for small areas. Moreover, it isn’t easy to transport. So companies must make the right decision before investing in this machine.

How Attachments Impact the Operating Weight?

As all other machines come with many attachments. Similar mini excavators also have many types of attachments. All these attachments have a specific purpose. Plus, all attachments have a major effect on the operating weight. So to clearly know all the attachments, keep reading this section. Plus, this section will explain the weight these attachments add to the total weight.

Bucket—12”/63 lb:

Buckets are the common attachment that can easily lift up the soil. Plus, this attachment is used in sloping, backfilling and leveling.

Auger—285 lb:

The common purpose of augers is to dig holes. Moreover, augers help to break hard surfaces and eliminate debris.

Hydraulic breaker—659 lb:

Breakers resemble augers, so these can break hard material. But breakers have more power than augers. The common purpose of breakers is for demolition, breakdown and more.

Clamp—218 lb:

A clamp is another famous attachment that helps in the removal of debris. Moreover, this attachment can lift up heavy objects.

Grapple—200 lb:

Grapples are another famous attachment to pick, transport and organize debris. The plus point of this attachment is that it can help in many material-handling tasks.

Common Mini Excavator Operating Weights

The weight of the compact excavator may vary based on the model. The following is the list of models, along with their weight:

| Model Operating weight (lb) | Horsepower (hp) | Digging depth (ft) |

| Bobcat E10 | 2,593 | 6 |

| John Deere 26G | 6,110 | 8.5 |

| Kubota KX057-5 | 12,346 | 12.75 |

| CAT 308 CR | 20,077 | 15.2 |

How to Determine A Mini Excavator’s Weight?

Suppose you need to learn about the weight of the mini excavator. Then the better solution is to check the manufacturer’s manual. In this manual, everything is present about the mini excavator. So you will know the exact weight of the machine.

While if you have decided to rent a mini excavator. Then you must go for HIXEN mini excavator because it is a better option. Moreover, before using the machine, make sure to read the manual properly. So you will know all rules, limitations and way of operation.

How to Choose the Right Size Mini Excavator?

Which excavator is the right fit for your job? If you don’t know, then you must consider the requirements of the project. The following are some requirements that will help you to choose the right machine:

Digging depth:

Make sure to rent an excavator with more digging depth according to the project. Commonly large excavators have more digging depth than small ones.

Horsepower:

Make sure to check the horsepower of your machine. After knowing power, find the attachments that suit best if the project demands more power. Then you should buy a powerful machine.

Reach:

The lifting capacity and reach of all machines may vary. Some machines have large arms. So these can easily deal with various heights and loads. That is why you should check the dump height of the machine.

Attachments:

Commonly mini excavators come with many attachments. But some attachments are more powerful than others. So you must check whether the machine has many attachments. Moreover, you should also check whether all these attachments can support the machine.

Type of boom:

Three forms of booms are present in mini excavators. These include swing, fixed and knuckle. Swing booms can move down, up and side. At the same time, the other two forms can’t move more or have limited motion.

Mini Excavators vs. Standard Excavators

As we know, mini excavators are small in size. So this machine can help with many tasks. But I don’t think that it can be a better solution for all jobs. In some jobs, you need to have a machine with more power. So here standard excavator can help you.

This section will highlight some differences between both machines. So you will get a better idea about which option is the best.

Versatility:

Both excavators are versatile. But the horsepower of a standard excavator is more compared to a mini. So it can support more attachments.

Bucket capacity:

Due to the large size of the standard machine, the bucket size is also big. Moreover, standard buckets have more digging depth.

Reach:

Standard machines can easily handle heavy loads and reach higher. While mini excavators can reach tight areas, that is better for small projects.

Cost:

Mini excavators have less cost because of their small size and less power.

Job:

Mini excavators are an ideal choice to work in small and narrow areas. In comparison, standard excavators are an ideal option for working in challenging areas.

Loaded Weight vs. Unloaded Weight

When you want to measure the weight of the mini excavator, then make sure to compare load vs. unloaded weight.

Unloaded weight is the weight of the machine when it has an empty bucket. Moreover, when the machine doesn’t have attachments, it gives unloaded weight.

Loaded weight is the weight of the machine when it has filled the bucket. Moreover, when an attachment is added to the machine, it gives loaded weight.

There is always a loaded weight limit in each machine. So every operator must follow this limit. Otherwise it:

- can tip the machine

- will break the machine’s parts and minimize the lifespan

- can harm the operator on the job site.

Conclusion:

We have described the weight, features and other factors about mini excavators. Now we got the idea that the size of mini excavators is 5,000 and 10,000 pounds. This weight is similar to the weight of an African elephant. After all these, you must know the requirements for your job. So you will get an idea of which excavator is the right fit. You will also know what weight will be helpful in your tasks.

Once you know the weight of the machine, then it helps you in many scenarios. These include

•Transport

•Lifting it with a crane

•Dragging

Make sure to keep these factors in mind on which the weight of the machine is based. These include attachments, models and job sites. While if you have to perform large or heavy work. Then make sure to invest in the powerful mini excavator!