Meta Description: To know the basic pump issues and their solutions usually arise in Excavator Hydraulic pumps, we have compiled this guide. After reading this guide, you will also know about many preventive measures.

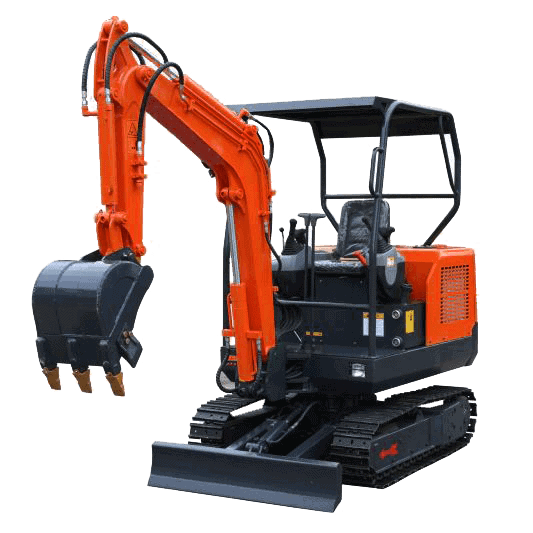

As we know excavator is the most famous machine in the construction industry. It has many types of components that work to get better results. One of these components is the hydraulic pump. However, this component is specially designed to work under strong conditions. But still, there are many issues that make it faulty.

It might be challenging to find the issue in the pump. But if you don’t notice such an issue, it can only affect the overall efficiency. With time, the effects of a faulty pump go over the entire machine. As a result, your machine can no longer be useful.

Excavator Hydraulic Pump Failure Warning Signs

Though the HIXEN Mini excavator is a useful machine so it also has many useful components. The hydraulic pump is among the vital components of the machine. You can also say this pump is the heart of the machine.

Commonly the pump is used for the plumbing of fluid that empower to machine to work. At the same time, this component can also undergo some common issues. As a result, your machine shows downtime and results in many repairs. So make sure to notice such issues as soon as possible. This way, you can save your money because of less repairing.

Warning Signs:

A hydraulic pump in the HIXEN Mini excavator is a strong component that performs hard tasks. But it does not mean that it can’t undergo any damage. There are many cases when this component fails to work suddenly. When you notice any failure in your component, then don’t neglect it and try to find out the warning signs. So you can act faster to resolve the issue to prevent the machine from damage.

Leaks:

In the exterior of the machine, hydraulic fluid is present. So there are many chances of leaking this fluid. At first, it is impossible to check the leaking because of no exterior sign. But you can check the difference between the performance of the machine.

Besides it, you may notice a decrease in the fluid pressure. So it is necessary to act faster and tighten all the seals. This way, you can protect the machine from major damage and breakdowns.

Beating and Knocking Sounds:

In good condition, the pump doesn’t produce any noise. When your pump is in bad condition or damaged, then you may notice any knocking and beating sound. The major sign of this sound is the presence of air because of less fluid pressure.

So, cavitation is produced in the system. It results only in the heating of the pump. With overheating of the pump, the parts of the machine start damaging. So make sure to notice this serious issue as soon as possible. Otherwise, there will be some major issues that will not be able to repair.

Increase in Temperature:

Make sure to keep the temperature of the hydraulic fluid to 81°C if the temperature goes beyond this limit. Then it starts damaging the component and quality of fluid. As a result, your pump fails, and fluid pressure is minimized. It causes overheating because of continuously increasing temperature.

It is among the major cause of the failure of hydraulic components. So it is necessary for you to notice this issue soon. Otherwise, this issue will become worsen and damage your machine. The major reason for this issue is the presence of debris in the fluid. So this issue slowly goes down to all components of the machine. Therefore check fluid pressure, aeration and common wear and tear.

Weak Final Drive Motor:

Another major sign is the weakness of the drive motor. The major cause of this weakness is the lack of fluid in the pump. So make sure to check the fluid level in the pump regularly. This way, you can avoid such issues.

Loud Noises, Grumbling Sounds, or Knocking:

The major sign of the pump failure is the loud sound. Commonly pumps don’t produce any sound. But when it becomes faulty, it starts producing grumbling noise. If you are experienced, then you can notice such a sound. But many times, you can’t notice it easily.

Usually, the major reason for this sound is aeration and cavitation. But there are also many other reasons which you should check.

What are the Most Common Causes of a Hydraulic Pump Failure?

Till now, you get an idea about all the signs of pump failure. Now we are going to discuss the causes of this failure. After knowing the causes, you can correct them before they become

Contamination in the Pump

The hydraulic system is designed to work with a fluid according to specifications. So when there is contamination of fluid in the pump, then it causes serious issues in the pump. As a result, the pump starts working very hard. Moreover, the major cause of contamination is water which causes corrosion. Plus, it also changes the thickness of the machine and causes overheating.

Besides water, dust, debris and other outside elements can cause contamination. So these can also seal other parts of the machine.

Failing Seals

The pump contains hydraulic fluid, so there is more pressure in it. As a result, this pressure forces the seal of the pump. After some time, because of more pressure, this seal starts leaking. This leak may either be minor or major and external or internal.

Whatever the leak is, it causes fluid loss and damage to the component. Moreover, internal links cause the fluid to move from one part to another. So your pump starts working very hard because of inefficiency.

Overpressure and Overloading

Though pumps are designed to work in strong and tough conditions, overloading and over-pressuring can cause the failure of the pump as the pump has a limit, so if it goes beyond the limit. Then there are many chances of failure and damage to the machine.

Air in Pump and in Fluid

The fluid of the hydraulic system also contains air in limited amounts. If the limit goes beyond, then it can lead to damage and inefficiency. As a result, your pump starts working very hard. Similar is the case in the pump which also causes many issues. So it is necessary to keep the air limit in the fluid and pump. Make sure to return the excessive air before using the pump for a long time.

Low Oil, Incorrect Oil, or Too Much Oil

Commonly hydraulic pump work according to specific parameters. So don’t neglect these parameters while operating the machine. Too low and too high oil can cause the pump to overwork. Then it causes an increase in the temperature and creates a non-uniform environment. So it is necessary to keep the oil limit according to some parameters.

How do I Maintain My Hydraulic Pump?

Though hydraulic issues are common, you can prevent such issues with a proper maintenance plan. This way, you can prevent your machine from a lot of repairs and money. The following are some common preventive measures. So make sure to follow all these to keep your machine in good working condition.

1. Check Oil Often and Replace on the Schedule:

As an operator, you must care about the oil change and schedule. Make sure to stick to a new schedule to increase the lifespan of your component. After you change the oil, check the wasted oil to notice any debris.

2. Use the Right Oil for the Machine and the Environment:

You should check the operator guide to know the right amount of oil. But you should also check the conditions of your working area. So it will help you to know and upgrade the oil amount in your machine.

3. Keep A Clean Machine:

Obviously, you don’t want to stop the machine from working because of no cleaning. So make sure to keep the machine clean all the time. Also, remove dust, debris and dirt from the pump to ensure smooth working. It will also prevent your machine from overheating and contamination.

4. Inspect Hydraulic Hoses:

Hoses have a direct link with the pump. So there are many chances of wear and tear on this component. It is why make sure to inspect hoses and remove debris, if any. Otherwise, it will only cause sudden failure of your machine.

5. Perform a Post-Mortem on a Failed Pump:

Suppose you have a failed pump and want to avoid failure for the next pump. Then it is necessary for you to post-mortem the failed pump. It will help you to know the reason for failure. This way, you can prevent the new and replaced pump from failing.

Conclusion:

Commonly a pump is a neglected part of any loader, excavator and truck. That is why there are many chances of issues in this component. Operators don’t notice such issues until they become worse. So if you are worried because of such issues in the pump, make sure to follow this guide to solve your pump problem!