Meta Description: Now technology has advanced, so many upgraded compact excavators are on the way. All of these are the backbone of any demolition and construction industry. Read further to check out more trends!

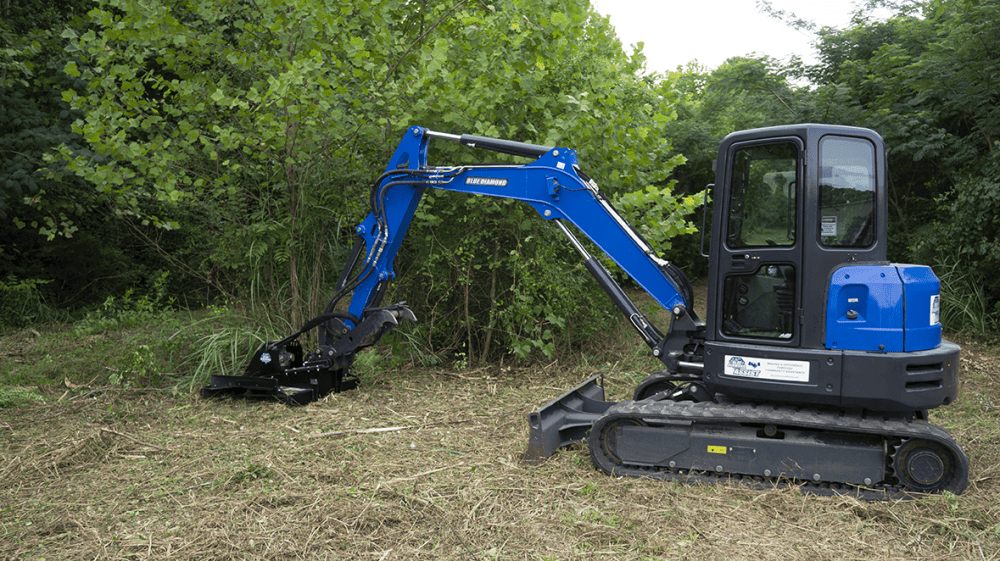

Mini excavators are the reliable, safe, and versatile backbone of different industries. This machine is also the best choice for many small farms and gardens.

However, many frustrating tasks are ahead in construction and demolition projects. But now, contractors may perform all these tasks with ease by using a mini excavator!

The Growing Excavator Market

Research showed an increase in the global excavator market by up to 4.9%. It is revealed that this market earned US$43.12 Bn in 2018. But this profit will increase to US$69.14 Bn by 2026. In the US, the excavator market earned almost US$ 10.62 Bn in 2018.

But in the European countries, there was not much increase in the market. The reason was continuously increasing environmental regulations imposed on industries. In comparison, Asian countries showed an increase in the excavator market upto US$ 18.32 Bn in 2018. The reason was continuously increasing infrastructure investments.

The trend to smart excavators in 2022

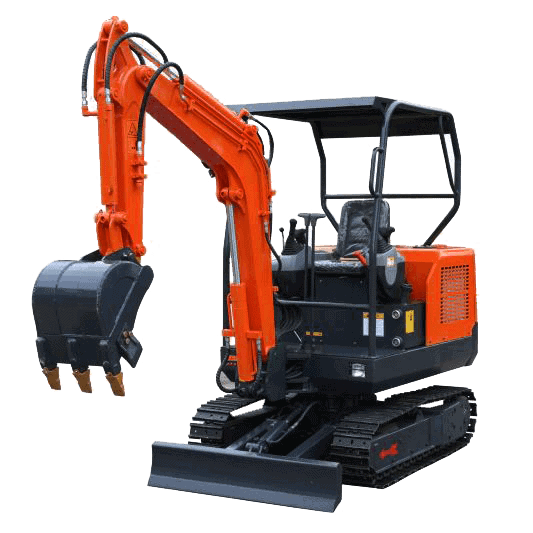

The excavators have been in use for many years in the industries. So, it is hard to say that some parts of the excavators are changed since the 1950s. Now many new machines and versions of excavators are introduced in the market. However, all these look the same from the outside but are not similar on the inside, like HIXEN Mini Excavator.

In 2022, there were introduced many new versions and technological applications. All these are now used in many industries because of their high efficiency and performance. Now excavators come up with improved efficiency, easy operation, and upgraded cab. Not only this, the machines have digital sensors, cameras, and radii.

Overview of the upcoming trends and developments

Reduced and configurable tail swing:

Though HIXEN Mini Excavator and new versions are on the market. But the most recent version of excavators has reduced tail swing. Through swing, contractors determine the space which is necessary for machine operation. It means small swings are flexible for confined areas.

Another common thing in mini excavators is small space rotation. Now many types of tight tail swings have been introduced in 3.5-ton machines. However, tight swings influence the stability of handling heavy items. That is why mini excavators have the option to configure a swing in the machine.

Improved cab design:

Another major advancement in mini excavators is the improved cab design. It is designed to give more comfort and convenience to the operator. The seats of the cab are adjustable and heated with more control. Not only this, the cab has a stereo system with Bluetooth connectivity. So the operator may enjoy enough space for the legs and head.

Improved operation:

Another major benefit of using a mini excavator is its improved operation. The soft-touch materials and efficient grip make it easy for operators to run the machine. Not only this, there are many flexible options coming from the joystick.

These allow the operator to easily run the machine without moving their hands. Joystick performs and maintains all the functions. Most of the time, the machine has electronic control. So, it allows the operator to load specific materials. As a result, it increases efficiency and reduces energy use.

Digital displays, LED, and extended video:

Now mini excavators come up with digital displays, LED, and extended video options. So, it becomes easy for the operator to read out information and monitor the machine. Through high-resolution and flexible cameras, operators may see different views. It is easy for the operator to monitor the front, back, bucket, and boom to ensure safety. Through digital displays, operators may see many camera views and screen configurations. Besides, displays allow operators to enjoy touch screens to connect with other devices.

GPS technologies are now introducing many accurate wireless systems. All these help to connect the machine data with remote devices precisely. When these systems are connected with the latest sensors and smart features. So these gather all the analytics and ensure efficiency, security, and performance. Through GPS, the machine’s efficiency and operation may be improved. Not only this, but GPS also avoids collision.

In simple words, GPS, along with GNSS, helps to direct the machine. Besides, these systems allow the machine to collect information and monitor performance.

Remote control:

Now mini excavators and their latest version have come up with a remote control feature. As a result, these controls allow the operators to safely operate the device. The remote control feature is an ideal option for controlling a machine in a harmful environment. Besides, control may minimize safety risks and possible harm during operation.

The wireless network of the machine allows operators to run the machine for a long distance. Besides, operators may stop the machine immediately in an emergency. The reason is that machines have minimal command delay.

Depth guidance systems and ‘set and go’ programming:

Now mini excavators have sensors. These are used to check the position of the boom, arm, and bucket. Mini excavators also have a depth check system to check the desired depth for the project. Using a depth system, operators may dig the depth or plan a new depth. Commonly the systems accurately dig upto half an inch. All the information about digging depth is displayed on the panel. So, operators may check the distance, grade, and depth.

Through systems, operators may fill the accurate depth. Besides, these help the operator to reach the grade as soon as possible with no cutting. The systems allow the operator to automate the machine completely or partially during automation, boom, arm, and bucket move. As a result, it will be easy for the operator to set and check the depth.

Adjustable angle blades:

Another major advancement in mini excavators is the adjustable angle blades. Operators may angle the blades from left to right up to 25 degrees and up and down up to 13 degrees. These angles help the operator to grade at a better position.

Moreover, these angles offer stability to the machine during digging o rough grounds. Operators don’t need to put much effort into digging on rough grounds. Special thanks to the adjustable angle blades.

Predictive and easier maintenance:

Another major advancement in the machine is easy maintenance. As a result, it minimizes the maintenance cost because of remote control operation. Through remote, operators may collect and monitor the information and deliver proper maintenance.

Many manufacturers have introduced the CMMS. The purpose of this system is to ensure operators easily access the data through the internet. Not only this, operators may access performance, position, and other data through GPS. All these systems allow the operator to check efficiency and operation rate.

Electric-powered excavators:

An important innovation in the excavator industry is the transformation to electric power. Now, many new versions of mini excavators are introduced that use electricity. It means there is no need for fuel or diesel to run the mini excavators. The major issue with fuel-used machines is their effect on the environment.

According to research, almost 25% of carbon dioxide is emitted all over the world. From this 25%, almost 6% emit from equipment. Continuous emission of carbon dioxide made it necessary to introduce electric power.

In 2019, a mini excavator of almost 2.5 tons was introduced. This excavator came up with a 300 Kw battery lifetime that may last for almost 7-9 hours. Now many small excavators have been introduced of almost 1 ton to 6 tons have. These use 8Kw to 43 Kw battery for the whole day. These only need 2 hours of charging.

Final Verdict:

With the increase in residential, commercial, construction, and demolition tasks. There is a continuous increase in the demand for mini excavators. That is why excavator companies are now trying to introduce new machines. Now many manufacturers have introduced the latest version of excavators.

Using mini excavators, contractors may work efficiently and smartly. Besides, the machines make operations easy, maintenance secure, and data management. Not only this, contractors may perform the job in detail!