The construction industry is continuously growing. The reason is the continuously increasing population globally. No doubt, the construction industry has made many contributions to the economy when it comes to using mini excavators.

FACT: A study revealed that the construction of buildings utilizes almost 35% of energy. In comparison, there are almost 45% of energy-related carbon dioxide emissions.

Though there are many climatic issues in the world, the construction industry is trying green energy solutions; here comes the mini excavator that is transferred to electricity.

Why are mini excavators a good candidate for electrification?

Zero-emissions at point-of-use:

With the increase in carbon dioxide emissions. There is the production of many climatic issues. So, the government is now forcing standards for zero emissions. These are applied either on on-way or off-highway applications. Now many zero-emission vehicles are running in the urban cities. All these follow the strict rules of zero-emission.

It is why there is also the need for electrified machines. Here comes the mini excavator with electric parts. The parts show similar performance and productivity as the diesel parts show. These are the reasons why constructors are using it in indoor applications. Electric machines don’t emit fumes and carbon dioxide.

Reduced noise pollution:

With more use of zero-emission vehicles, there is less noise in cities. In the past, machines caused more noise during operation. But due to advancements, this issue has been resolved. Now all the machines are quiet and produce less noise.

There is much need for a reduction in noise pollution in construction areas. It is not only satisfying for people and workers. It is also beneficial for the health of passers. The mini excavator is not only quiet. But it also provides better results and completes the job properly.

As less noise improves the communication between operators and workers. This way, operators may guide other workers about the work.

Interoperability:

When it comes to interoperability, there is no difference between electric and diesel mini excavators. It means both counterparts show the same performance. Moreover, both these are more productive. The only difference is that electric engines show changes vastly. So it gives better performance and productivity in the project.

Decreased maintenance:

Now top-quality HIXEN mini excavators don’t need fuel to run on the project site. So there is no need for coolants and oil filters. As a result, there is less chance of maintenance of the machine. Therefore operators may save cost which was required for maintenance. So they may invest this cost in some other important chores.

What are some of the challenges that electric mini excavators still face today?

Battery packaging requirements:

Though all the machines are designed for diesel instead of batteries, so there is much need for better packaging as packaging is always an important and challenging task. But still, manufacturers need to pack the parts.

Keep in mind batteries consume less energy compared to fuel. So the batteries require an additional part called a thermal management system. In comparison, fuel-based machines don’t require such parts.

Cooling and heating management:

Though all the battery parts are packed in tight Areas, so there is more need for the machine to perform under all temperatures as the machine is compact because of less space in it. So it is not possible to add a component for heating and cooling. A battery never works under 0 degrees Celsius.

There are many things that a customer must consider. All these help to make a perfect purchase of batteries. You should know the following:

Whether the machine has the capacity to meet the project requirements?

After knowing the answer to this question, you may choose the right battery. Always choose the machine that gives you many benefits. Moreover, always choose the cost-effective machine. Always choose the machine that has less operating costs.

The benefits of battery-operated machines are:

- Flexible

- Free operation

- Low emission

- Quiet

All these are the necessary factors to choose the right machine. Suppose you have to use the machine in indoor applications. Make sure to must find the machine with these features. The applications are kindergartens, parks, hospitals, and more. So machines with batteries can handle all the tasks carefully. In simple words, there is a bright future for electric vehicles.

Comparison of operating costs:

The operating cost of the electrified machines is less. These are almost one-third of diesel engines. Special thanks to the latest technology that made it possible. The main reason of less cost is the efficiency of the machine. Moreover, electric parts are less costly compared to diesel parts.

Moreover, there is no need for maintenance of electric parts. Only the diesel parts, such as oil filters and V belts, need maintenance. So when all these are removed, there is no need for maintenance. All these are the Reasons Why people prefer to use electric machines.

Minus point: Range

Though new electrified machines have many benefits, these also have some disadvantages. The main is the limited ranges said by Hauser Paul. So if you have to use the mini excavator all day, it is necessary to charge it for at least an hour at noon. For this, you need to connect it with the power grid. In comparison, you may also charge it in phases during work. You also have the option to replace the battery.

Battery Technology:

For the power consumption of electrified machines, batteries are present. So these machines collect power from such batteries. Another name for these traction batteries is standard batteries. These are connected in series and parallel. This connection allows the machine to get voltage and capacity. There are many batteries in a machine. These are based on the need of the construction project.

Suppose the mini excavator had a weight of 1.9. Then there is a need for 15-kilowatt hours traction battery. While if the machine has more weight. Then there is a need for 20 batteries with 300 kilowatt hours.

Though batteries are expensive when bought individually. So it is recommended to buy interconnected batteries for the machine. That is why each machine owner must choose connected batteries. These will not only give more power but also be cost-effective.

Power sources for batteries: untapped potential in China:

Obviously, after charging the batteries, machines get electricity. While in some cases, this power comes from the grid power. Not only this, there are many better alternatives. These include photovoltaic systems and biogas systems.

The better option is to consume your own electricity to run the machine. Otherwise, you may get electricity from grids.

Conclusion:

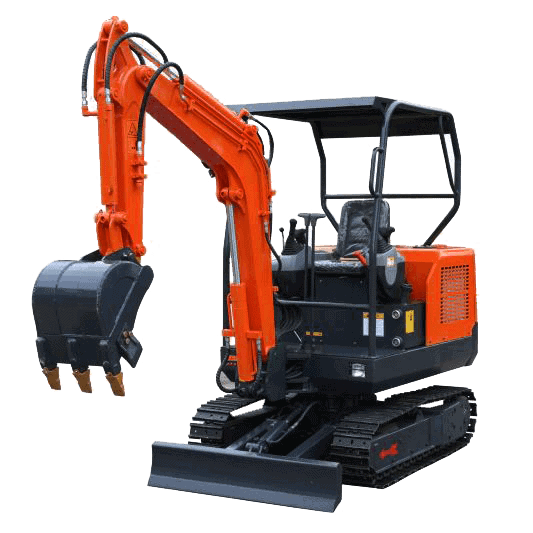

With the increase in the construction industry, there is a rapid increase in demand for machines. Here comes the most versatile and durable machine. What do we call it? We call it a mini excavator, the best of all excavators.

Among the different types of mini excavators, the best is the HIXEN Mini excavator. All the excavators and other machines are transferred to electricity from diesel. That is why people commonly prefer this machine for the handling of all tasks.

The average life of a mini excavator is 10,000 hours. Moreover, there are many major attachments to the machine. These include hydraulic pumps, final drives, swings, buckets, and more. It is possible to replace and repair all these parts!