Meta Description: Are you conscious about the working of attachments in Mini excavators? If yes, then read the expert guide about the compactors and breakers working that make mini excavators work flawlessly!

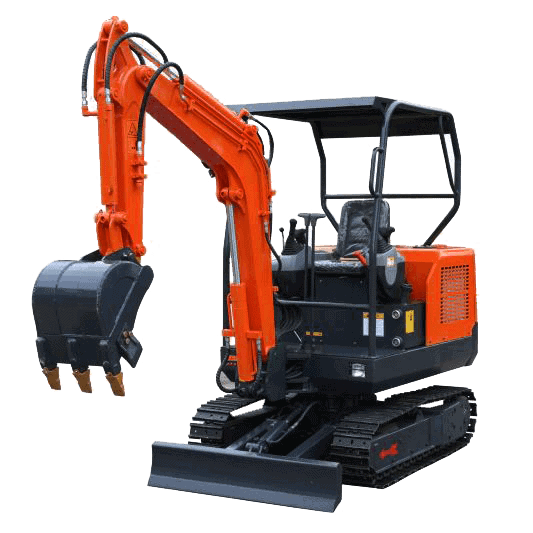

A mini excavator is a famous tool in the construction and demolition industry. Now many contractors prefer to use this machine because of its small size and less weight. Using this machine, contractors may smoothly grade soil. Not only this, the machine help to lift and transfer materials from one place to another. No doubt, you may not perform such tasks using the hammer and vibrating machine.

The plus point is that many manufacturers are now manufacturing this machine. The reason is the continuously increasing demand for mini excavators. So, you may have many options to choose from for your project.

Breakers

Breakers have been in use since a half-century ago because of basic technology. The breakers have a pressurized piston in a hose. However, his piston lifts up and down continuously. So it loses the hardened soil in less time. The bit in the beaker hit the concrete and rock surface and fractured it.

Almost three pressure systems are present in the breaker to fracture the materials. Only one, among these three help to break. These include hydraulic, nitrogen, and a combination of the two. Commonly breakers come up with hydraulic pressure devices. Moreover, make sure to only find the device that is best compatible with your machine.

Vibratory Compactors

Besides breakers, vibratory compactors are mostly in use. These are not like HIXEN Mini Excavators that help to drive steel beams.

Many manufacturers introduced new series of compactors in 2015. Now many contractors use these machines to perform many tasks. A new series of compactors with a plate is introduced. These series have a plate to spread vibration in a uniform manner.

Other Attachments that Work with Mini Excavators?

Mini excavators are used in a variety of small or large tasks. These may be landscaping, demolition, picking of debris, construction, agriculture, and other industries. So, each contractor must choose this valuable tool.

The machine comes up with many attachments that make it more useful. When you have to change one attachment to the next, however, the Quick Coupler will help you to swap from one attachment to another. In simple words, it is the best investment that will give you a better return.

All the attachments of mini excavators are also helpful with much other equipment. These may be skid Loaders, Multi Terrain Loaders, and Backhoe Loaders.

WHAT ARE THE TOP MINI EXCAVATOR ATTACHMENTS?

1. HYDRAULIC THUMB:

The most famous attachment of your mini excavator is the hydraulic thumb. Using attachment, you may boost the efficiency of the machine when the bucket and thumb are in your hands. After the use of the thumb, it folds back quickly. With the help of a shut-off valve, you may use other tools and keep the thumb withdrawn.

The thumb of the mini excavator helps to maintain the bucket rotation. Not only this, the thumb is used to match the tip radius, width, and space of the bucket. A mini excavator has two configurations of thumb with a bucket size of 457 mm in length.

Thumbs are an ideal and versatile option for many small and large tasks. These may be cleaning the site, moving pipes, blocks, and rocks, and many other tasks. You may also use thumbs in landscaping, farming, construction, and plumbing.

2. AUGER:

Bedside thumbs and augers are also the best attachment tool for mini excavators. This tool is used to drill holes in fencing, sign, trees, and shrubs. It is also useful in many agriculture, landscaping, and construction works. Augers commonly deliver the torque necessary for productivity in all soil types.

Augers are more versatile, safe, and quick compared to manual digging augers. This tool is manufactured with more weight, power, and pressure system.

All the drives of mini excavators allow the 2-inch hexagon shaft to operate the auger in the soil. This way, more torque is produced compared to a round shaft.

3. TILT ROTATE COUPLER:

We know the importance of a quick coupler in a mini excavator. But nothing is more versatile than a Cat Tilt Rotate coupler.

This versatile attachment help to rotate your machine in no time. The Coupler helps the machine rotate at 360 degrees and tilt at 40 degrees. Many types of couplers are now available. To fit with the red grapple, an S-type tilt coupler is the better option. For standard buckets without changing the position, the Cat Pin Tilt coupler is best.

Tilt couplers offer extra efficiency and productivity to the mini excavator. Moreover, the machine now comes up with an advanced display to easily choose the function. Through Tilt rotate coupler, you may improve precision and position.

4. STATIC WHEEL COMPACTOR:

Static wheel compactors are an ideal choice for many projects. Whether you need this wheel for landscaping, plumbing, and earth working, these compaction wheels must be your first bet. The main factor that made these wheels more famous is cost-effectiveness.

Commonly wheels use machine weight and apply force to the ground for compaction. The wheels just need 6-9 passes to completely compact the soil. But the passes may vary based on the required compaction levels.

In many soil conditions, vibration excavators are not a good option. Here static wheel compactors are the better choice to get good compaction.

5. HYDRAULIC VIBRATORY PLATE COMPACTOR:

To perform basic construction tasks, mini excavators have hydraulic vibratory compactors. Not only in soil but this attachment is also used in sand and gravel. Using this attachment, contractors may prepare the land by adding concrete.

As a result, the tool slope compaction on different sites. Due to the low price, this attachment is much famous in pavers and general contractors. Now many residential and commercial contractors are using this attachment.

6. The integrated pressure flow control:

This attachment is used in many machines but is most common in a mini excavator. The tool helps to stable the pressure flow and improve reliability. The machine attachment also has a hose routing to reduce damage to the hose and bearing.

7. OPERATING TIP:

Mini excavators don’t act like a hammer, so not much downward force is required to operate. The up-and-down movement of the plate compactor delivers much compaction. It means there is only a need for the plate to come into contact with the ground for compaction.

While when you provide much downward force to the plate. It may experience more force than the normal requirement. As a result, plates don’t move up and down.

8. RAPPLE:

Commonly the 9 tons mini excavators use grapples. These are the better attachment for small and even large tasks and removing materials. The grapples use 3-5 fine configurations to completely handle demolition tasks.

However, using grapples, contractors may hold many materials while loading in the truck, at the time of unloading the materials, even large materials. Contractors may use the low curved jaw to improve speed and penetration.

Conclusion:

In the end, we proudly say that nothing is better and more helpful than a mini excavator. This small machine is a worthy addition to your project. This small machine help in landscaping, construction, demolition, and other tasks. The machine comes up with attachments to help you in performing small tasks.