If you pick the wrong telehandler weight, your construction project could be delayed, less efficient, or even cost more to move. Let’s break it down and figure out what weight class is best for your job.

Telehandlers generally fall into three weight categories: under 11,000 lbs (compact), 11,000–33,000 lbs (medium), and 33,000+ lbs (large). The right choice depends on your lifting needs, site size, and transport options.

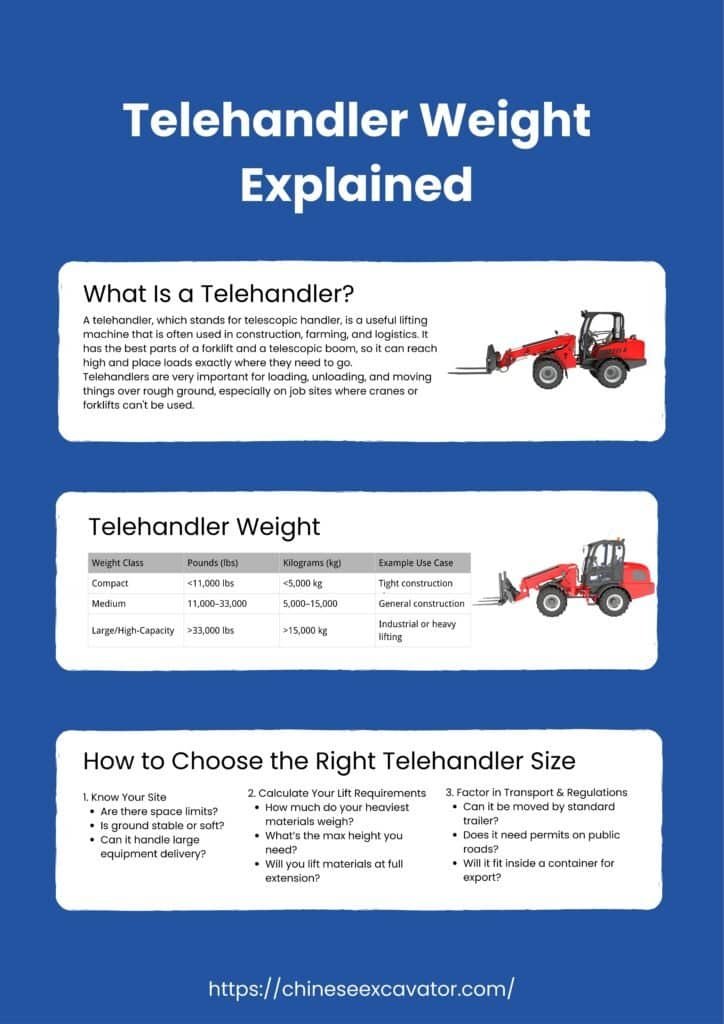

Not sure yet? To help you make the best choice, let’s look at the different types, sizes, and lifting limits of telehandlers.The image below is an infographic of telehandler weight to quickly give you a sense of the relevant information.

Table of Contents

ToggleWhat Is a Telehandler?

A telehandler, which stands for telescopic handler, is a useful lifting machine that is often used in construction, farming, and logistics. It has the best parts of a forklift and a telescopic boom, so it can reach high and place loads exactly where they need to go.

Telehandlers are very important for loading, unloading, and moving things over rough ground, especially on job sites where cranes or forklifts can’t be used.

If you want to add a telehandler to your fleet permanently or rent one, it’s important to know things like its weight and capacity so you can use it properly.

Telehandler Weight: How Much Does It Typically Weigh?

Weight varies significantly between brands and models. Here’s a quick breakdown of telehandler weight classes:

Telehandler Weight Chart (lbs and kg)

| Weight Class | Pounds (lbs) | Kilograms (kg) | Example Use Case |

|---|---|---|---|

| Compact | <11,000 lbs | <5,000 kg | Tight construction sites |

| Medium | 11,000–33,000 | 5,000–15,000 | General construction |

| Large/High-Capacity | >33,000 lbs | >15,000 kg | Industrial or heavy lifting |

The Bobcat TL38.70 weighs about 18,000 lbs (8,160 kg), and the JCB 550 telehandler weighs about 24,000 lbs (10,886 kg).

Some heavy-duty telehandlers, like the 10K and 12K models, can weigh between 27,000 and 33,000 pounds, especially when they have all of their counterweights and attachments.

Weight is important because it affects how things are moved, how much fuel is used, and how easy it is to get to the job site.

Which Telehandler Weight Class Is Best?

Choosing the right weight class isn’t just about power—it’s about your job site’s needs and limitations.

Small Telehandlers (<11K lbs):

- Ideal for small to mid-size sites with limited access.

- Easier to ship (can fit into standard containers or smaller trucks).

- Suitable for indoor or urban construction.

Medium Telehandlers (11K–33K lbs):

- Balance between power and portability.

- Perfect for mid-size commercial builds or infrastructure projects.

- Commonly used on general construction sites.

Large Telehandlers (>33K lbs):

- Built for high-capacity jobs like steel lifting, roadwork, or mining.

- May require special transport due to size and weight.

- Not suitable for soft ground or narrow access points.

Choosing wisely helps avoid delays, prevents overkill, and ensures safety.

Lifting Capacity: How Much Can a Telehandler Lift?

Many buyers put lift capacity first, and they have good reason to.

Most telehandlers can lift between 4,000 lbs (1,800 kg) and 12,000 lbs (5,400 kg). But that lifting capacity can change a lot depending on:

- Boom extension: The farther you extend, the less it can lift.

- Boom angle: Lower angles reduce stability.

- Counterweight design: Heavier machines handle more load.

A 6K telehandler (like the CAT TH255) is often used for residential builds, while a 10K model (e.g., Bobcat V923) supports high-rise or steel frame construction.

Important: A telehandler rated for 10,000 lbs won’t lift 10,000 lbs at full boom extension. That’s a common misconception.

Always review the load chart provided by the manufacturer. Overloading can tip the machine or damage its hydraulics.

How Does Weight Impact Telehandler Lift Capacity?

Weight and lift capacity go hand-in-hand. A heavier telehandler generally supports higher loads because:

- It has a stronger counterweight system.

- It provides more ground stability.

- Its frame and axles are built for strength.

However, heavier doesn’t always mean better.

Consider the tradeoffs:

- Heavier machines may sink into soft soil.

- Transportation becomes more expensive.

- Larger size makes maneuvering in tight areas difficult.

For example, a 27,300-lb telehandler (like a 10K JLG or SkyTrak) can lift nearly 10,000 lbs to a height of 53 feet. Impressive, but not suitable for every site.

Sometimes, a mid-weight 8K or 6K model gets the job done faster and more efficiently.

How to Choose the Right Telehandler Size for Your Project

Here’s a simple 3-step method to choose the right telehandler:

1. Know Your Site

- Are there space limits?

- Is ground stable or soft?

- Can it handle large equipment delivery?

2. Calculate Your Lift Requirements

- How much do your heaviest materials weigh?

- What’s the max height you need?

- Will you lift materials at full extension?

3. Factor in Transport & Regulations

- Can it be moved by standard trailer?

- Does it need permits on public roads?

- Will it fit inside a container for export?

For example, a 6K–8K telehandler is perfect for most mid-size builds in African or Middle Eastern regions due to easy shipping and wide compatibility. Heavier machines like a 10K CAT TL1055 are ideal for industrial contractors with access to strong ground and heavy lifting needs.

Also, if you plan to rent before buying, check with your local telehandler rental company to test a few sizes before committing.

Summary

Before you buy or rent a telehandler, make sure you know the right weight for safe lifting, easy transport, and smooth project flow.