Se você está indeciso entre minicarregadeiras de esteiras e de rodas, este blog pode responder às suas perguntas. Vamos analisar suas vantagens e desvantagens para ajudá-lo a tomar uma decisão rápida.

As minicarregadeiras com rodas são adequadas para terrenos duros e planos e têm custos de manutenção mais baixos; enquanto as minicarregadeiras sobre esteiras oferecem melhor estabilidade e tração em terrenos macios e acidentados. Sua escolha deve depender das condições do terreno, do clima e do orçamento.

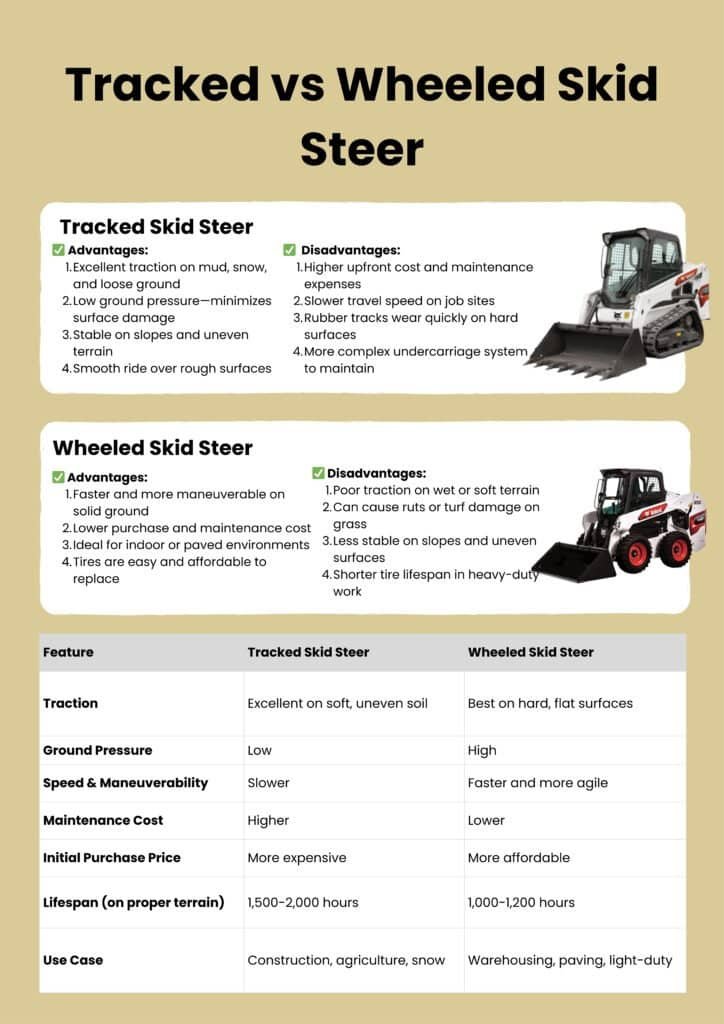

Abaixo está uma análise comparativa detalhada para ajudá-lo a fazer a escolha certa com base em suas necessidades reais de trabalho.

Índice

AlternarMinicarregadeira sobre esteiras

Vantagens

As minicarregadeiras sobre esteiras são feitas para trabalhar em condições difíceis. Se você trabalha frequentemente em terreno lamacento, arenoso ou irregular, uma unidade sobre esteiras lhe dará a estabilidade e a aderência que você precisa.

As minicarregadeiras sobre esteiras são ótimas para locais de trabalho difíceis e durante todo o ano porque têm melhor tração, estabilidade e flutuação em solo macio ou irregular.

Modelos sobre esteiras como o Caterpillar 279D3 e o Kubota SVL75-2 são feitos para ter o máximo contato com o solo. Isto reduz a pressão sobre o solo e protege superfícies frágeis. Suas esteiras abaixam o centro de gravidade, o que os torna mais seguros em terrenos inclinados. Você pode encontrá-los muito nas indústrias de paisagismo, silvicultura, demolição e remoção de neve.

Desvantagens

Embora poderosas, as minicarregadeiras sobre esteiras nem sempre são a opção mais prática, especialmente se você estiver gerenciando custos.

As minicarregadeiras sobre esteiras custam mais antecipadamente, exigem mais manutenção e se movem mais lentamente em comparação aos modelos com rodas, o que pode afetar a produtividade em grandes locais planos.

A substituição das esteiras de borracha pode ser cara e o sistema de material rodante é mais complexo. Por exemplo, as esteiras são mais suscetíveis ao desgaste quando utilizadas frequentemente em concreto duro ou asfalto. Você também precisará fazer um orçamento para ajustes regulares de tensão e substituições de trilhos.

Minicarregadeira com rodas

Prós

As minicarregadeiras com rodas são a melhor escolha para trabalhos em terreno sólido, como estradas, estacionamentos e interior de edifícios.

As minicarregadeiras com rodas geralmente são mais baratas, mais rápidas e mais fáceis de cuidar. Eles se dão muito bem em solo duro, seco e plano e podem se mover facilmente em espaços pequenos.

As pessoas gostam do Bobcat S650, CASE SR210B e New Holland L320 porque são rápidos e fáceis de mover. Seus pneus os tornam melhores para cidades e fábricas, onde precisam se movimentar facilmente e manter os custos baixos. Também custa menos e leva menos tempo para trocar os pneus do que as esteiras de borracha.

Contras

No entanto, as minicarregadeiras com rodas têm limites de desempenho – especialmente quando as condições ficam lamacentas ou irregulares.

Os modelos com rodas têm menos tração, baixo desempenho em solo macio e podem causar mais danos à superfície do que as máquinas sobre esteiras em determinadas condições.

Seu contato limitado com o solo significa maior pressão sobre o solo, o que pode fazer com que afundem ou girem na lama, neve ou areia solta. Usar um modelo com rodas para remoção de neve ou em um campo agrícola com terreno irregular provavelmente reduzirá a eficiência.

Minicarregadeira com esteira e com rodas: principais diferenças

Escolhendo entre um minicarregadeira sobre esteiras ou rodas se resume a compreender as diferenças específicas. Aqui está uma comparação lado a lado:

| Recurso | Minicarregadeira sobre esteiras | Minicarregadeira com rodas |

|---|---|---|

| Tração | Excelente em terrenos macios/irregulares | Melhor em terreno plano e sólido |

| Velocidade e manobrabilidade | Mais devagar; raio de viragem mais amplo | Mais rápido; torneamento apertado, ideal para áreas confinadas |

| Pressão sobre o solo | Mais baixo – menos danos à grama | Maior – pode causar cio |

| Custo Inicial | Mais alto | Mais baixo |

| Manutenção | Acompanhe a substituição cara e a manutenção mais frequente | Trocas de pneus mais fáceis, menor custo de manutenção |

| Conforto de passeio | Mais suave, especialmente em terrenos acidentados | Esburacado em superfícies irregulares |

| Durabilidade em superfícies | Não é ideal para pavimento ou concreto | Ótimo para superfícies internas e pavimentadas |

| Aplicativos | Paisagismo, remoção de neve, silvicultura, agricultura | Estradas, armazéns, canteiros de obras |

| Principais modelos | CAT 279D3, Kubota SVL75-2, JD 317G | Bobcat S650, CASO SR210B, NH L320 |

Esta comparação ajuda a esclarecer por que entender o seu ambiente do local de trabalho e carga de tarefas é essencial antes de fazer uma compra. Esses fatores também afetam diretamente o ciclo de vida do seu equipamento e custos operacionais—uma preocupação fundamental ao procurar por um Minicarregadeira sobre esteiras ou rodas para venda.

Melhores aplicações para cada tipo

Minicarregadeiras sobre esteiras brilhar em:

- Locais de trabalho molhados, lamacentos ou com neve

- Zonas de construção pesada

- Paisagismo em terreno delicado

- Inclinações íngremes ou terreno irregular

- Agricultura (por exemplo, preparação do solo, áreas florestais)

Minicarregadeiras com rodas são mais adequados para:

- Construção urbana em superfícies planas e pavimentadas

- Obras rodoviárias e demolição de interiores

- Manuseio de materiais em solo sólido

- Uso diário com orçamentos leves de manutenção

Se você está procurando a máquina certa para uso agrícola, as minicarregadeiras sobre esteiras oferecem melhor desempenho em ambientes com solo pesado. Muitos pequenos agricultores preferem minicarregadeira com rodas vs sobre esteiras opções para transporte mais fácil e trabalhos compactos.

Como funciona a minicarregadeira com esteira e com rodas

A principal diferença está em como eles dirigem e como funciona o material rodante:

Um sistema de rodas dentadas e rolos move as esteiras de borracha nas minicarregadeiras sobre esteiras. Esta configuração uniformiza o peso e proporciona melhor aderência.

As minicarregadeiras com rodas têm quatro rodas movidas por motores hidráulicos. Por terem uma área de contato menor, exercem mais pressão no solo, o que facilita a movimentação em superfícies duras.

Conhecer essa diferença mecânica o ajudará a descobrir que tipo de trabalho e terreno cada tipo pode suportar bem.

Quando escolher uma minicarregadeira sobre esteiras ou rodas?

Ainda debatendo? Aqui está uma regra simples:

- Escolha rastreado se você trabalha em:

- Lama, neve, cascalho solto

- Encostas, florestas ou terrenos acidentados

- Áreas de paisagismo sensíveis

- Escolha com rodas se você:

- Precisa de movimento rápido

- Trabalhe em ambientes fechados ou na calçada

- Quer reduzir seu orçamento de manutenção

Além disso, considere o Custo da minicarregadeira com esteira e com rodas ao construir sua frota. Os modelos rastreados geralmente custam de 15 a 25% mais, mas podem economizar tempo de inatividade no longo prazo se combinados com as condições de trabalho corretas.

Conclusão

Resumindo, minicarregadeiras sobre esteiras oferecem tração e flutuação imbatíveis para terrenos acidentados, lamacentos ou irregulares, tornando-os perfeitos para paisagismo, agricultura e remoção de neve. Por outro lado, minicarregadeiras com rodas fornecem velocidade mais rápida, custos mais baixos e melhor desempenho em superfícies planas e duras – ideal para trabalhos internos ou urbanos.

Sua decisão deve ser baseada no condições do local de trabalho, orçamentoe com que frequência você espera usar a máquina.

Se você estiver explorando opções confiáveis e econômicas em qualquer categoria, HIOSEN é especializada na exportação de minicarregadeiras usadas de alta qualidade de marcas líderes como GATO, Lince, Kubota, e CASO. Com 15 anos de experiência no setor, estamos aqui para ajudá-lo a fazer a escolha certa.

Perguntas frequentes

Você pode colocar trilhos em uma minicarregadeira com rodas?

Sim, mas as pistas sobre pneus proporcionam desempenho limitado. Eles são úteis para aderência temporária, mas não correspondem à estabilidade de um sistema de pista dedicado.

O que é melhor em uma minicarregadeira, esteiras ou rodas?

Depende do terreno. As pistas são melhores para superfícies macias e irregulares. As rodas são melhores para velocidade e manobrabilidade em terreno sólido.

Quais são as desvantagens das rodas de esteira?

Altos custos de substituição, velocidades de deslocamento mais lentas e durabilidade reduzida em superfícies duras.

Por que as pistas são melhores que os pneus?

As esteiras proporcionam melhor flutuação e estabilidade. Eles são mais versáteis em lama, neve ou cascalho e causam menos danos à grama.