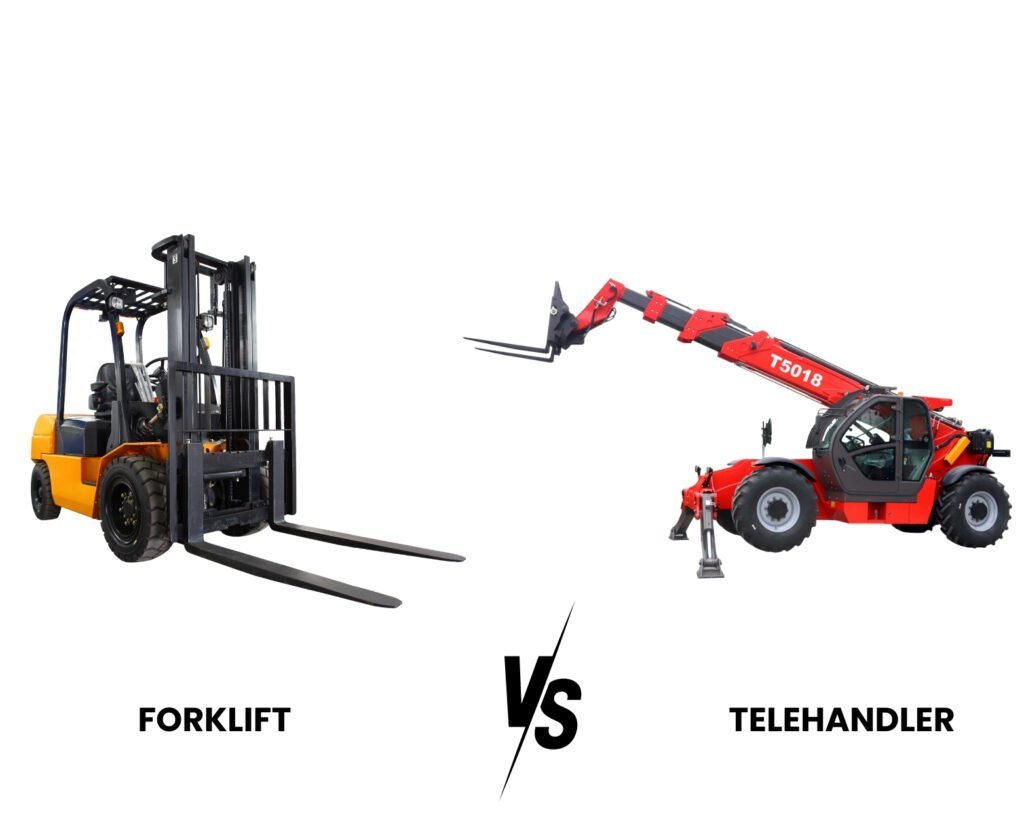

When choosing lifting equipment, many buyers focus only on price or brand. In reality, the biggest difference between a telehandler and a forklift is how well the machine fits your actual working conditions. Terrain, lifting height, job flexibility, and application type all play a critical role. Understanding these differences can help construction companies, contractors, and equipment distributors avoid costly mistakes and improve productivity.

Let’s break down telehandler vs forklift differences so you can choose the right machine with confidence.

جدول المحتويات

تبديلWhat Is a Telehandler, and How Does It Work?

A telehandler, also known as a telescopic handler, is designed for rough terrain and demanding construction environments where reach and flexibility matter most.

A telehandler uses a telescopic boom to lift, extend, and place materials at heights or forward distances. It supports multiple attachments, making it suitable for diverse construction tasks.

Telehandlers are widely used on construction sites, farms, and infrastructure projects. With attachments like forks, buckets, and lifting hooks, one machine can replace several others. Brands such as CAT, JCB, and Bobcat are popular choices. For buyers with budget limits, used telehandlers offer strong performance at a much lower cost.

What Is a Forklift Best Used For?

Forklifts are material-handling machines built for stability, efficiency, and repetitive lifting tasks in controlled environments.

Forklifts are best suited for warehouses, factories, and ports where loads are moved short distances on flat ground. They focus on efficiency rather than reach.

Forklifts are commonly used in logistics, storage facilities, and manufacturing plants. They are easy to operate, maintain, and transport. Brands like Toyota, Komatsu, and Hyundai dominate this segment. For distributors and small businesses, used forklifts are a cost-effective solution with quick return on investment.

Telehandler vs Forklift: Key Differences

Telehandlers and forklifts are both designed for lifting and moving materials, but they are built for very different working environments. A telehandler, also known as a telescopic handler, is primarily used on construction sites and rough terrain. It features a telescopic boom that can extend forward and upward, allowing materials to be placed at height or over obstacles. A forklift, on the other hand, is optimized for efficiency, stability, and repetitive material handling on flat, solid surfaces such as warehouses, factories, and ports.

One of the most important differences is lifting reach. Telehandlers can lift loads several meters forward and upward, making them suitable for multi-story construction projects. Forklifts are limited to vertical lifting and short forward reach, which works well for palletized goods but limits flexibility on complex sites.

Terrain capability is another key factor. Telehandlers are usually equipped with large tires, four-wheel drive, and higher ground clearance, enabling them to work on mud, gravel, and uneven ground. Forklifts generally require smooth, hard surfaces to operate safely and efficiently.

In terms of versatility, telehandlers clearly stand out. With multiple attachments available, one telehandler can perform tasks normally handled by several machines. Forklifts are more specialized and focus on speed and efficiency in material movement rather than task diversity.

Below is a simplified parameter comparison to highlight the practical differences:

| Parameter | Telehandler | Forklift |

|---|---|---|

| Max Lifting Height | 6–18 meters | 3–6 meters |

| Forward Reach | Yes (telescopic boom) | Very limited |

| Terrain Capability | Rough terrain, construction sites | Flat, paved surfaces |

| Typical Load Capacity | 2–5 tons | 1.5–5 tons |

| Attachments | Forks, bucket, jib, platform | Forks, clamps |

| Primary Application | Construction, agriculture | Warehouse, logistics |

| Operating Speed | Moderate | High |

| Skill Requirement | Higher | Lower |

Performance and Application Comparison

Performance should always be evaluated based on real job requirements, not just specifications. Telehandlers perform best in dynamic environments where lifting height, reach, and adaptability are required. They are commonly used for placing materials on upper floors, moving loads across uneven ground, and handling bulky items that cannot be managed by standard forklifts.

Forklifts excel in high-cycle operations where speed, precision, and consistency are critical. In warehouses or distribution centers, forklifts can move pallets quickly and efficiently with minimal downtime. Their simpler structure also means easier maintenance and lower operator training costs.

Which is Better For Construction Projects?

Construction projects often demand flexibility, lifting height, and adaptability to changing site conditions.

For most construction sites, telehandlers are the better option due to their reach, versatility, and ability to work on rough terrain.

Telehandlers can move materials across muddy ground, lift loads to upper floors, and handle multiple tasks with attachments. This reduces the need for extra machines. Construction companies in Africa, the Middle East, and South America often prefer used telehandlers to balance performance and cost.

Common Attachments for Telehandlers and Forklifts

Attachments play a major role in expanding machine functionality. Telehandlers are designed to support a wide range of attachments, making them highly versatile. Common telehandler attachments include pallet forks, buckets, lifting hooks, jibs, and work platforms. This allows one machine to handle material lifting, loading, and personnel access.

Forklifts use fewer attachments, but they are highly efficient within their scope. Standard forks are the most common, followed by paper roll clamps, bale clamps, side shifters, and fork positioners. These attachments are mainly used to improve efficiency and safety when handling specific types of loads.

Should You Buy a Telehandler or Forklift?

Deciding whether to buy telehandler or forklift should start with your actual working conditions rather than the machine price alone. If your projects involve construction sites, uneven terrain, or lifting materials to higher levels, a telehandler is usually the more practical choice. Its telescopic boom and wide attachment compatibility allow one machine to handle multiple tasks, reducing the need to invest in additional equipment.

If your daily operations are focused on warehouses, ports, or factories with flat ground and repetitive material handling, a forklift is often the smarter investment. Forklifts are faster, easier to operate, and more efficient for palletized goods. They also require less operator training and generally have lower maintenance complexity.

Budget is another critical factor. For many buyers, especially in developing markets, purchasing brand-new equipment is not always cost-effective. In this case, choosing a used telehandler or used forklift from a reliable exporter can significantly reduce upfront costs while maintaining dependable performance. Well-known brands such as CAT, Volvo, Komatsu, SDLG, and Bobcat are built for durability and continue to perform well even after years of service.

Ultimately, the right decision depends on how often the machine will be used, the type of jobs it will handle, and how quickly you expect a return on investment. Matching the machine to the application is the key to long-term profitability.

Final Thoughts

The choice between a telehandler and a forklift depends on where and how the machine will be used. Telehandlers are ideal for construction and rough terrain applications requiring flexibility and reach, while forklifts remain the best solution for flat-surface material handling. For many buyers, sourcing reliable used machines from experienced exporters offers the best balance between performance and cost.